![]()

Frying Oil Monitor: DOM-24 was officially implemented in India by the Food Safety and Standards Authority of India (FSSAI), and health departments and ministries from countries such as Iran, Iraq, and the UAE. This instrument allows to numerically monitor the deterioration level of oil that can pose health risks like cancers.

Inline Concentration Meter: The quality of products is monitored every second when an inline concentration meter is mounted directly on tanks or pipelines. It can provide a sense security and peace of mind in the prevention of defective materials.

Non - destructive Brix Meter. Equipped with 7 different wavelengths and 20 LED light sources, it is the world’s smallest non – destructive Brix meter. Fast measurement speed of 1.2 seconds, ELI to avoid stray light, and shape that fits the size of fruits; all provides enhanced user experience.

Viscometer. In addition to the deliciousness defined by sweetness, saltiness, and sourness, a viscosity is a safety indicator that defines softness. Texture of food or drink going down one’s throat can be measured by viscosity and it directly ties with food safety for the elderly and young children.

ATAGO products contribute to safety and security in other various settings and applications.

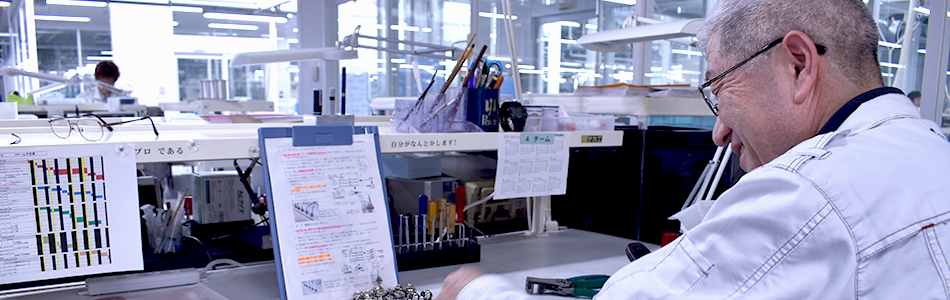

“Made in Japan” connotes durable, compact and easy to use, low maintenance instrument that stick to the basics, and confidence that fast repair service, and great before and after customer centric services are provided.

For example, the average time from receiving instrument to when a quotation is provided takes less than 4 hours. In most cases, the repair work is done within the same business day. Even for more complex higher accuracy instruments, the turnaround time is estimated to be 3 business days or less. This is how fast ATAGO provides repair services to our customers.

In addition, ATAGO service centers are available in 46 countries for customers outside of Japan. The service technicians across the globe are continually invited for service training in Japan so that customers do not have to send their instruments to Japan for service related inquiries. ATAGO strives to maintain this condition and environment for customers to be able to get the service they deserve in their own or nearby countries. Through measuring devices, ATAGO connects and maintain sustainable relationships with our customers globally.

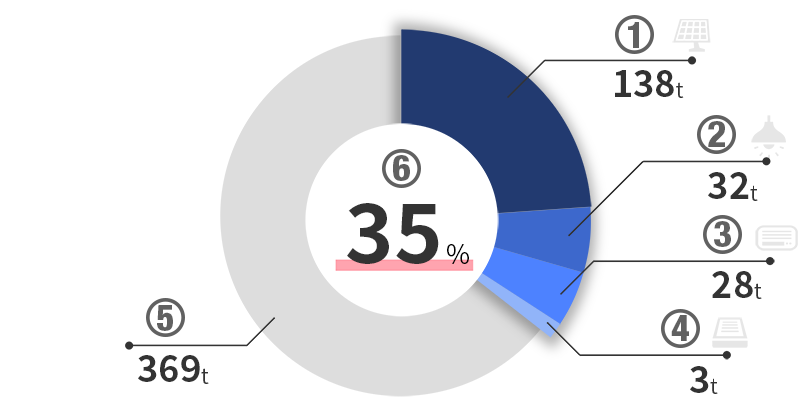

CO₂ emissions and reduction distribution

Based on the decision of the 45th meeting of the Leaders Summit on Climate held on April 22, 2021, Atago declares carbon neutrual by 2050. We have been reducing greenhouse emission since 2013. We are targeting to reduce emissions by 46% until 2030, but aiming for 50% and higher to be more challenging.

In plastic injection molding system, the end pieces called “runner” is regrounded into smaller pieces and recycled. For example, about 14% of the housing case used for PAL series are made from recycled plastic materials.

The forms used in the instrument case is made from urethane. In a day, about 13kg (28.66lb) of end pieces are generated and it is repurposed as packing material. The shredded paper is also used as packing material.

When shipping back and forth between our external partners, we use a special "Return Box" that elimantes the need for any newspaper or other packing material.

Instead of discarding defective SUS pipes, we used them to put together a boy playing baseball, done by welding and buffing all in house. From this, our beloved "Nige Gosh-kun", who is always ready to run, was born.

Fruit is used in the manufacturing process of our IR Brix Meters. Because this model is becoming increasingly loved by farmers, production has increased and disposing of fruit has become difficult. We now reuse this fruit as bird food in our birdhouses.

Wow, it feels so good~

Summer in the Kumagaya region is the hottest in Japan. On such a day, the mister installed on one side of the large roof will operate. Yes, the secret pleasure is "diving through the mist curtain" from the sky.Your body and mind are soothed as if you were behind a waterfall.

One of the future initiatives will be to reuse the metal swarf from metal processing by melting to create ingots inhouse. For sustainable development goals, ATAGO will establish zero-waste factory.

Approved by the labor standards inspection office

Approved by the labor standards inspection office

ATAGO has been certified by the Kumagaya Labor Standards Inspection Office for partial exemption regarding organic regulations. Harmful organic solvents that are harmful to the human body are not brought into the facility. "Eco thinner" and "Neo Alcohol" that do not correspond to the solvents specified by the PRTR Law, Organic Law, and Specialization Law.

Bespoke Indulgence. A compiled wish list from the site operators, “I wish…I want…” came true in the hands of technical experts. A desk full of rational arrangement and functional gimmicks is reflected in the functionality and usability.

This picture shows the paint cans used for the sheet panels. The entire shelf is arranged in an orderly fashion like a palette of paints. There is a sense of satisfaction the neatness and cleanliness we feel is on the shelf.

There are no separating walls or pillars that visually blocks the manufacturing process. Without any sheathings, piping and wiring are exposed. These elements correspond to future production line changes and are truly sustainable architecture.

Three minutes before the end of the day is dedicated to organizing. The boxes and trays are placed parallel to the shelves one by one on its surface. This is a sustainable habit that leads into refreshed start the next morning.

Every morning and evening, a 10-minute standing meetings are conducted. This elongated space is shared across multiple departments for a quick progress check meeting. A quick drop in and out space provides hesitation free environment which prevents mistakes from happening.

Materials such as polyvinyl chloride that give rise to black smoke when they burn are not used in the products or accessories. From environmental conservation perspectives, ATAGO takes pride in using plant-based resins and polyolefin.

The concentration of metalworking fluid and oil mist volume is constantly monitored for “crisp and clear air” working environment. Mist collectors are placed in various locations, and in addition, only cutting oils that produces the least amount of oil mist is used.

Several workplaces maintain a temperature of 20.0 ° C in the summer, which naturally causes condensation. Aiming to prevent condensation on glass surfaces, 15 overhead circulators were installed.

Forklifts, lifts, lawnmowers, and turrets are all painted in sand beige + black, carefully washed, and even waxed. And each is stored in a designated spacec a fire station. Shedding light behind the scenes shows our love for sustainability.

ATAGO as a pioneer of measuring instrument manufacturer will continue to develop high-precision measuring devices utilizing years of cultivated technological know-hows.

Symmetric solar panels installed on the rooftop of a spaceship-like building.

An 18 meter tall symbolic tree with diamond-shaped leaves. (Ginkgo)