Oil Test Strips

― Is your oil still fresh? ―

Once oil degrades, it must be replaced with new, fresh oil. Continued use of old, degraded oil can have many negative consequences. Not only does it spoil the quality and flavor of food, it may also gravely impact the health of your customers. By managing the quality and condition of degraded oil using quantitative, objective values, you can determine just the right time to change out the oil. It can also be extremely useful in reducing costs and improving the quality and flavor of your food products.

Efficient management allows you to maximize the lifespan of oil.

Simply, place some oil on test strip.

Compare the color change in 30 seconds to the color chart on the bottle to check the AV (acid value).

Using lightweight aluminum for the bottles, not only it is easy to carry around, but it also protects test strips from moisture.

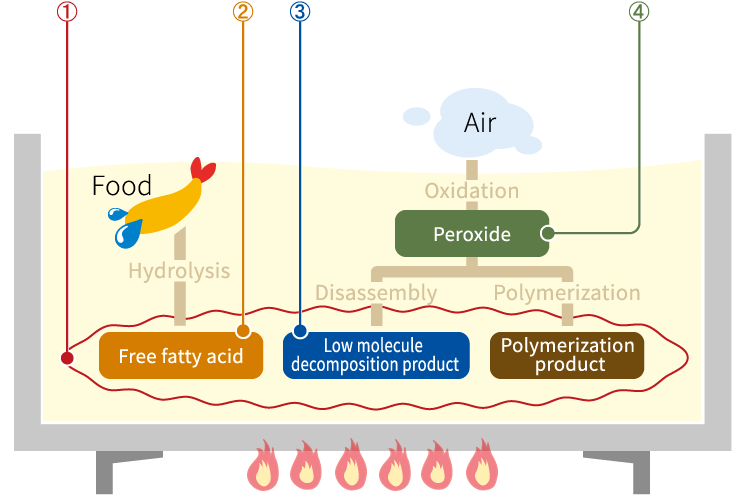

Why is old cooking oil bad?

When oil becomes old, one of the components of oil, unsaturated fatty acid induces toxic peroxidation.

With further progress, if rancid oil is consumed, it can cause “heartburn” and “nausea” and pose health risks.

To utilize oil effectively, we recommend periodical monitoring with AOM-03.

Determining oil oxidation at home can be done by color or smell, but in professional kitchens and production sites, the methods below are used.

① Total Polar Materials (TPM)

A method used to determine the degradation of frying oil. Total Polar Materials (TPM) refers to all products present in frying oil due to oxidation processes, including free fatty acids, products of low molecular weight decomposition, and polymerized substances. The EU has adopted a value of 25 to 27% as their acceptable upper limit for fats and oils.

② Acid Value (AV)

Acid Value or AV is an index that denotes the amount of free fatty acids caused by hydrolysis. Acid value is a suitable method for evaluating the degree of oxidation for frying oils. Many AV test strips, which can be easily measure the value, are used at food production sites.

③ Carbonyl Value (CV)

It is a measurement denoting the amount of aldehyde and ketone produced in frying oils to determine degradation. Carbonyl compounds can be a good indicator of thermal oxidation. In addition, as the threshold is small, it will impact the smell of fats and oils greatly.

④ Peroxide Value (POV)

Peroxide is generated when oil is exposed to air, causing the unsaturated fatty acids to absorb oxygen. Peroxide value can also be used to measure hydroperoxide but for frying oil the indicator is by decomposition or polymerization.

| Instant noodles | The acid value of fats and oils contained in noodles should not exceed 3 or the peroxide value should not exceed 30. | Standards for Foods, Food Additives | |

|

In fats and oils of noodles dried by oil treatment should be 1.5 or less. The acid value of fats and oils used for oil processing of noodles should be 1.5 or less. |

Japanese Agricultural Standard | ||

|

Confectionery processed with fats and oils (containing 10% or more of fats and oils) |

Selling products that conform to the following (a) and (b). (a) For confectionery products, the acid value of fats and oils contained in their products should not exceed 3, and, the peroxide value should not exceed 30. (b) The confectionery should not exceed an acid value of 5 or more in the fats and oils contained in the product or, the peroxide value should not exceed 50. |

Confectionery Guidelines | |

| Bento box and side dish |

As raw materials: Use those with an acid value of 1 or less (but excluding sesame oil) and a peroxide value of 10 or less. Frying with fats and oils: If the acid value exceeds 2.5, replace with fresh fats and oils. |

Health Code for Lunch Box and Side Dish | |

| Western-style confectionery |

(1) Component specification of raw materials: acid value 3 or less, peroxide value 30 or less (2) Products shall conform to the following standards ①The acid value of fats and oils contained in the product does not exceed 3. ②The peroxide value of fats and oils contained in the product does not exceed 30. |

Healthy Norms of European-style Confectionery | |

| Edible vegetable oils and fats | Oil with low degree of purification | Acid value of 0.20 to 4.0 or less. (Cottonseed, sesame, rapeseed, peanut, olive, palm olein, palm stearin, mixture, flavor oil) | Japanese Agricultural Standard |

| Refined oil | Acid value of 0.20 or less (Olive oil has an acid value of 0.60 or less) | ||

| Salad oil | Having an acid value of 0.15 or less (the one prepared with olive oil has an acid value of 0.40 or less) | ||