Concentration Control - Essential for Water-Soluble Cutting Oil Management

With only 2 buttons

An intuitive refractometer

anyone can use!

Your questions answered!

Cutting Oil Daily Management Q & A

Controlling concentration is regarded as the most important.

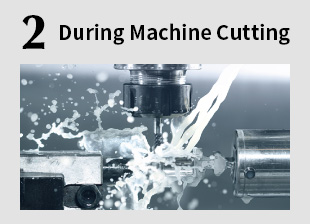

It is necessary to maintain the proper concentration because the liquid`s concentration changes over time.

Refractometers are most commonly used.

Cutting oil concentration might be too low. Please measure the liquid and adjust to the proper concentration.

Cutting oil concentration might be too high. Please measure the liquid and adjust to the proper concentration.

The oil might be degraded. Please make sure it is at the proper concentration.

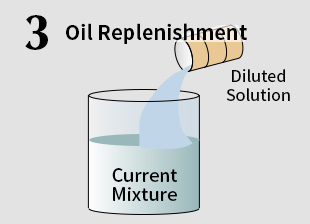

Maintaining the proper concentration often helps extend the life of the cutting oil.

First check that the concentration is at the right level.

There are water-soluble cutting oils with excellent foam suppression characteristics as well.

In order to suppress the growth of bacteria, it is essential to maintain the proper pH and concentration of the cutting oil.

You can reduce cutting oil cost by monitoring the concentration with an objective, numerical value ( by refractometer) instead of relying on an operator`s experience and intuition.

Even a new, inexperienced worker can monitor the concentrataion easily with a refractometer and avoid problems!

Refractometers Used Across Various Industries

Since the hole of the steering knuckle is where the drive shaft passes through, if the machined surface is flawed, it directly effects the performance, so high accuracy is required. Since the material is aluminum, to avoid risks of welding, a high Brix% concentration is maintained around 13.1 to 13.5%.

Due to various traditional techniques being handed down through the ages, it is not possible to disclose exactly how and in what process the concentration is controlled. However, it`s not hard to imagine that every single part of the small body requires high precision and quality control.

For machining aluminum parts, the cutting oil concentration is 3 to 7%, and for difficult-to-cut materials, it is 8 to 11%, which is slightly higher. In summer, the concentration tends to be higher due to evaporation, so cutting oil has to be diluted to a lower concentration. On the other hand, in the winter, cutting oil is being kept slightly higher concentration. They are even keeping in mind the slight differences from weather when it comes to concentration control.

The body is made of materials with high resistance to amines in cutting oil.

NFC (Near Field Communication) that allows transfer data just by holding the device near a smartphone/NFC reader.

Supportive

Aftercare Service

Direct From

The Manufacture

MADE

in Japan

2 year Warranty

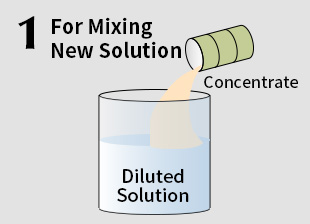

Water-soluble cutting oil is used by diluting concentrates with water. The management (concentration control) of these dilution ratios stabilizes the machining accuracy,

maintains quality, and prevents future issues.

In the initial mixing, a refractometer can be used to check to make sure it is diluted to the proper concentration. The proper concentration can vary depending on the type of oil used and manufacturing conditions. In genreal, the proper concentrtion for cutting oil is from about 5 to 10%.

The dilution ratio is often provided by the oil supplier/manufacturer, but users should also research what dilution ratio meets the characteristics and accuracy requirements for their process. The improvement of manufacturing technology and skills by numeralization is encouraged.

It has been said that doing rough machining at low oil concentrations and finnishing at high concentrations has led to significant cost savings per month on raw materials.Material cost reductions be achieved by using a refractometer to properly manage the useage levels, but does not often occur due to relying on the intuition of the workers.

By measuring the concentration of the tank, septic tank, and injection port, it is possible to check the function of the filtration tank, such as the effect of mixing hydraulic oil and more.

Proper concentration control has the effect of slowing the progress of oil degradation, which leads to cost reduction. In addition, preventing degradation is more environmentally conscious as it decreases waste.

The concentration of the solution changes over time due to the evaporation of water and accumulation on machine tools. To bring the solution back to the initial concetnration, management is done by measuring with a refractometer.

Dry, irritated skin is a concern when the concentration is too high and workers come in contact with the liquid. On the contrary, machines easily rust if the concentration is kept too low.

It is also possible to meausure the concentration while the water and concentrate is being mixed into the tank, though best results occur when the sample is homogeneous.

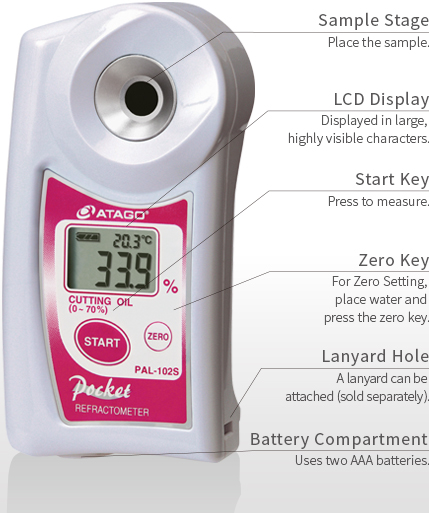

| Range | Cuttiong oil : 0.0 to 70.0 % |

|---|---|

| Resolution | Cuttiong oil : 0.1% |

| Accuracy | ±0.2% |

| Temperature | 10 - 100℃ |

| Power Supply | 2 x AAA Batteries |

| Intemational Protection Class | IP65 Water resistant |

| Dimensions & Weight | 5.5 x 3.1 x 10.9cm 100g(main |

Easy to carry set of PAL-102S and PAL-pH.

includes pH calibration standard solutionpH4.01, pH6.86, pH9.18 or pH4.01, pH7.00, pH10.01

Refractometer concentration measurements are possible for emulsions, solubles and chemicals. Note that milky white samples and samples containing other oils may not have stable measurements. After putting the sample on the sample stage, stir it with a plastic utensil (no metal) to get stable values.

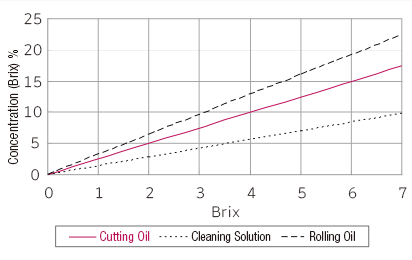

A refractometer measures in the Brix% scale, which is based on Refractive Index. Therefore, when measured with a refractometer, the Brix% and the actual concentration of the oil is different. In daily concentration control, the Brix% can be used as is, or converted to the actual concentration. To convert the Brix% to the actual concentration, a graph can be created and the coefficient can be calculated.

For example, if 10g of concentrate and 90g of water are mixed together, a 10% solution is made. Let's say this solution measures 4% Brix on a refractometer. Then, the conversion factor will be 10.0 / 4.0 = 2.5. Therefore, the actual concentration of the diluted solution is 2.5 times the Brix % (value measured on the refractometer).

* The release agent model cannot measure black colored samples, only white/opaque samples.

* Please contact ATAGO for continuous measurement type, as it depends on the operating environment.

Looking ahead to the IoT era, we have developed a compact inline refractometer that can be installed anywhere.

It has already been implemented by many customers, including automotive manufacturers.

It is possible to continuously measure water-soluble cutting oil, cleaning solution, mold release agent, quenching oil, etc.

Conventional pH meters easily break due to the shape of glass electrodes. If they break, additional work and thouroug cleaning is needed. PAL-pH's glass electrode has been successfully developed to withstand heavy loadsHigh durability means it reduces the risk of contamination, can be used without hesitation, and doesn't even need to be stored in a solution. This model is recommended for those who use cutting oil containing amines.

| Range | pH0.00 - 14.00 |

|---|---|

| Resolution | pH0.01 |

| Accuracy | pH±0.10 |

| Calibration | Calibration(pH4.01,6.86,9.18) |

| Temperature compensation | 10 - 40℃ |

| Sample Volume | 0.6mL |

| Power Supply | Size AAA alkaline battery × 2 |