Delice is a dairy product manufacturing industry in Tunisia. Not only dairy products, but they also manufacture soft drinks and water. They are using ATAGO`s bench top refractometer RX-5000i for product control and development in the soft drink sector.

ATAGO case study for Refractometer RX-5000α and RX-7000α

QWhich models of ATAGO refractometer you are using?

AWe have two different models:

• RX-5000α for our Quality Control Lab

• RX-7000α for Karachi Technical Center

QHow long have you been a user of ATAGO products?

AWe are a user of ATAGO products for the last 12 years. Initially we had the ATAGO Abbe Refractometer NAR-1T and from 6 years ago we shifted to these digital automatic refractometers.

QWhat samples you are testing on the refractometers?

AWe use them to determine Refractive Index of raw materials like IPA, flavors, fragrance silk etc.

QYour feedback regarding the instrument`s performance?

AWe are fully satisfied with the performance of ATAGO digital automatic refractometers. The accuracy, precision, and reliability of the instrument results is acceptable.

Top Glove Sdn. Bhd. Is the world's largest manufacturers in Malaysia and supplies various styles of gloves which are used in different industries from medical, food to cleaning.

To measure the components of their high quolity gloves, RX-5000α is used for measurement of acid, alkaline, CN concentration and total solid compnenets.

RX-5000α contributes to their quick and accurate measurement process.

RX-5000α

Nestle Pakistan is the largest manufacturer of dairy products and juices in Pakistan.

They have two plants that are using ATAGO products, Nestle Sheikhupura Plant and Nestle Kabirwala Plant.

Below are details from their user at Nestle Kabirwala Plant.

QHow long have you been using this product?

AMore than 6 years.

QWhat samples you are testing in refractometer?

AChecked refractive index of butter, fats and oils, Brix and total solids in milk products.

QBefore this instrument how did you test your samples?

AWe measure the brix and total solid by using our internal reference method approved by Nestle(oven method) and for this minimum 6 hrs. were required. Since then we have shifted to ATAGO Refractometer.

QYour feedback for instrument performance?

AWe are fully satisfied with performance of Atago Refractometer.

The instrument requires no service, is very easy to use and it gives most accurate and reliable results.

Our product is released on the basis of its results.

Shangrila Foods Private Limited manufactures various sauces and seasonings.

With the RX-9000i benchtop refractometer`s useful pre-programmed user scales, they can easily change between Brix%, NaCl %, and NaOh% measurements. RX-9000i was chosen for it`s wide measurement range and high accuracy to measure even slight differences in their products for high precision in test results and helps control product quality.

RX-5000i

QWhat is your feedback on our model which you are using?

AWe can check so many scales like RI, Butyro and Iodine Value on our Rx-7000i, This is really a great deal for us. Edible Oils like Sunflower, Rice bran, Soya etc all can be checked using different scales at 40 deg or even at room temperature. Once we create the scale for Iodine Value, this can be used to check. This saves us a lot of time.

QAre you satisfied with our after sales support?

AConsistently giving us good service, no room to complain.

RX-5000i

QWhat is your feedback on our model which you are using?

AWe are using Atago RX-5000i model for our fruit & vegetable pulp application, to check Brix, and we are very much reliant on this model for all our quality needs. Mother Dairy also uses Rx-5000i to check the Ghee (saturated fact) Butyro value and Refractive Index at other plants.

QAre you satisfied with our after sales support?

AAlways eager to help us in time of need.

RX-5000i

QWhat is your feedback on our model which you are using?

AKetchups can be a tricky sample. The viscosity affects the Brix readings. We needed a sureshot value of Brix across batches. The repeatability of the results is what we depend on. Rx-5000i fully ensures that results are bankable batch after batch.

QAre you satisfied with our after sales support?

ANo problem with them, we are very happy with the performance and with after sales service.

RX-5000i, PAL-3 and DR-A1

QWhat is your feedback on our model which you are using?

AWe really appreciate the versatility in the products of ATAGO. For our syrups, we use DR-A1, for our pulps we use Rx-5000i and for quick testing at floor level we use PAL-3. ATAGO has been a trusted partner for us.

Pomegrante pulp, mango pulp and guava pulp are our main products. Different modes in Rx help us determine the accurate Brix which is crucial for our exporting needs.

QAre you satisfied with our after sales support?

AThey are always ready to help for our technical needs and support our staff whenever we ask for help. Sometimes, when the chemists change, and new ones need to be trained; we can bank on ATAGO INDIA.

RX-5000i

QWhat is your feedback on our model which you are using?

AWe use this model for our Food Application lab in R&D and sampling division. We are using 2 RX-5000i which offers high accuracy and quick results at desired temperature. Our samples are flavours and food additives.

In our R&D applications, we sometimes are not able to know what the RI of the product is. That’s why we need a reliable refractometer which we can use for discovery of RI. RX-5000i provides just that. We upgraded from RX-5000 to RX-5000i.

QAre you satisfied with our after sales support?

AWe are getting prompt service for our calibration calls and AMC too.

All started in 1919 when Isaac Carasso is the first Danone yogurt with fruit pulp in Barcelona. In Barcelona, Spain? Yes, the first yogurt with fruit pulp was made in Spain, and only in 1929 is founded Danone in France. However, the group went international in fact with the merger of BSN with Gervais Danone in 1973, which brought together two ambitious companies, creating a powerful drive that was destined for success. Danone arrived in Brazil in 1970, through a partnership with Dairy Pocos de Caldas. Already innovative at the time, launched here a new and very tasty product: yogurt with fruit pulp.

Use of the RX-5000i equipment ATAGO is essential for the quality control of our products; it is possible to monitor the correct degree of Brix for the production of the best yogurt in the world happen.

RX-5000i

We like the big screen, big sample chamber which is easier for operator to fill oil and do cleanup. Precision and repeatability is excellent as well! Robust, user friendly design. (Food Chemist)

RX-5000i

QWhat is your feedback on our model which you are using?

ARx-5000i is an established model in all PEPSI plants in India.

We are considering the reading on Rx as a standard across all our plants. We maintain the highest level of quality for Brix in our sample. The readings are required to be accurate in the second decimal. This is possible on the Rx-5000i. We were earlier using Rx-5000Alpha and now have started upgrading all our models to Rx-5000i.

QAre you satisfied with our after sales support?

AYes, in fact we are regularly taking AMC and service visits across multiple states. So far, ATAGO INDIA has never given us any trouble during our much needed times.

RX-5000i

QWhat is your feedback on our model which you are using?

AIt matches ISO 22241, and that is what matters. We need high accuracy in the 5th decimal of RI and this model Rx-5000i fulfills that requirement. We are also very happy with the global and domestic references of ATAGO for Urea measurement. Many of our clients are in fact using ATAGO, so that gave us a lot of confidence.

QAre you satisfied with our after sales support?

AThey helped us out with an extra service when badly needed by our auditor, so we are really impressed.

RX-7000i

QWhat is your feedback on our model which you are using?

AWe are using Rx-7000i for over 7 years now. It gives us consistent results and we are very happy with the performance of this machine. It hardly breaks down ever.

We are using RX-7000i to also cross check with our suppliers. With such a high accuracy, we can always count on the supplier quality and maintain our internal QA standards.

QAre you satisfied with our after sales support?

AOur AMC is timely serviced, and ATAGO INDIA always helps us out in case of any problem.

RX-7000i

QWhat is your feedback on our model which you are using?

AWe really like Rx-7000i’s cleaning ease. Due to multiple samples, we often clean a lot. The shape of the prism helps us clean easily.

Typically fragrances are very expensive, so we use a very little quantity to check on this model.

QAre you satisfied with our after sales support?

AWe have taken AMC as well from ATAGO, and are delighted with their service.

QWhat is your feedback on our model which you are using?

AWe have been using ATAGO products for the last 8 years now. PRM is truly solving our problem of measuring sample inline and strong co-relation with the bench-top model RX-5000i We measure NMMO, and Soft finish resin used to polish fibres, and both the models show accurate and correct readings. We pass our batch based on the readings.

QAre you satisfied with our after sales support?

AATAGO INDIA has supported us fully by even giving a free DEMO Unit of Rx and PRM whenever we wanted. They really went the extra mile in making sure our plant runs uninterrupted.

RX-5000i

QWhat is your feedback on our model which you are using?

AWe really appreciate the user friendly features of Rx-5000i. Our sugar quality checking requires highest accuracy, and Rx fulfills that. We are using PAL series for all our farmers, and using Rx in the lab. The inter instrument agreeability is really impressive in case of ATAGO.

QAre you satisfied with our after sales support?

AHighly satisfied, no room to complain. Even for calibrations, we receive quick reply.

Cafés de Especialidad de Chiapas, S.A.P.I. de C.V (CAFESCA) is the only producer of lyophilized coffee in Mexico and Central America. We are located inside the Strategic Fiscal Precinct from Port of Chiapas (southeast of the Mexican Republic), the only one in the country at the seaport. We are a proudly chiapaneca company dedicated to the production of lyophilized coffee for national and international distribution. We are part of ECOM Group, one of the three main commercial businesses of coffee in the world.

lyophilized coffee, we used ATAGO refractometers at the EXTRACTION PROCESS to monitor the concentration of liqueur coffee or syrup, as a quality department we need to make sure that the product is under the requirements and to assure ourselves we use the model RX-5000i because it is automatic, easy to use, very stable, trustworthy and the calibrations take no longer than 3 minutes.Besides this model, our colleagues from the production department are using hand held PAL pocket refractometers to monitor the extracts. We use ATAGO because we have had excellent feedback and experience with the equipment, they are very precise and long lasting for the industrial use, and especially for the Instant Coffee, where a high or low concentration can influence our final product results and that is why the RX-5000i, gives us confidence to standardize the Brix suitable for concentrated coffee extract. The RX-5000i, gives us the confidence to standardize the Brix suitable for concentrated coffee extract.In the quality department we use the RX-5000i equipment to monitor the concentration of syrup, and from the percentage of Brix we process the analysis of acidity, filter soluble solids, and cupping (sensory) and last, we proceed to the lyophilization step, this is done once product meets the safety requirements and specifications.

Extracts tend to be diluted in 9.0 – 12% Brix.

Coffee syrup or extract: 50 – 56% Brix.

Written by: Eng. Karina Morales

Head of Quality Control

Cafés de Especialidad de Chiapas, S.A.P.I. de C.V (CAFESCA)

RX-7000i & SAC-i

QWhat is your feedback on our model which you are using?

ABoth RX and SAC-i models are user friendly, and do our job quite reliably. We are a pharma testing lab with high premium on reliability and accuracy, and that is why we need good equipment. ATAGO fulfilled our need.

QAre you satisfied with our after sales support?

AATAGO India engineers are very supportive and we really expect a good relationship going forward.

Bussan Food Materials Co., Ltd., is a company that manufactures and distributes processed fruits, juices, and syrups.

Their products are used for production of juices, ice creams, jellies, yogurt, candies, dressings, and sauces. These products are shipped out according to vendors' needs.

During their manufacturing process they use our hand-held refractometers and the RX-5000α Digital Refractometer for quality control.

Their office location is about a 5 minute-walk from the JR Asakusabashi station or Bakurocho station, and Toei Line Asakusabashi Station.

They moved to this nice new office location in August 2010.

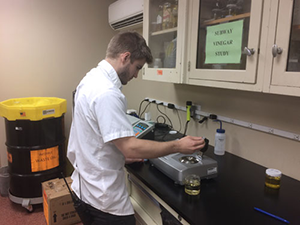

Our staff visited the technological development center located on the first floor.

QWould you tell us about your line of business?

AAt our technological development center, we strive to support production of high-quality products by using our longstanding technology towards product development, material receiving inspection, and product inspection.

Once you enter, you will see that many of their labs are walled with large windows.

Their technological development center was based on the concept of "Transparent Laboratory," and from the hallway employees and guests are able to observe the work being done in the laboratory.

They carry three each of the same instruments, and they are strategically situated so that measurements can be taken in sequence three at a time. Our RX-5000α is also placed in three stations.

QWhat are the inspection components for quality control?

AThey include, but are not limited to, Brix (sugar content), acidity, pH, color, sensory evaluation, foreign materials inspection, and bacteriological testing.

QWhat do you emphasize during quality control?

AWe strive to maintain fast and reliable service to provide our customers with safe and unfailing products. We set high operation standards and check our inspection apparatus so that we can always maintain exceptional precision.

Also, we work to improve our product quality by regularly training employees for sensory evaluation.

QHow do you inspect and calibrate our refractometers?

ABefore each usage we calibrate the refractometers with distilled water, and we also do a monthly calibration with 40% and 60% standard sucrose solutions to confirm on its accuracy. On top of that, we send our units to a 3rd party lab for annual calibration. Also, to increase the consistency of measurements taken at this lab and the labs at other production facilities, we use the same RX-5000 series to measure the same samples.

QHow user-friendly is the RX-5000α?

AI have always been using ATAGO's refractometers since I started working here. The first model that I used was an Abbe refractometer. Depending on the color of fruit juice, sometimes I had difficulties reading the scale due to it being too dark, but improvement was made quickly. From the original Palette type, it was improved into more accurate RX-5000, and now we use the RX-5000α. The RX-5000α is easy to use, and I feel it is what an ideal Brix measuring devise would be.

Thank you very much!

At the QC lab, we collect fruit juice with a spatula and place it on the sample stage of the RX-5000α, taking measurements one after another.

Though the samples are all fruit juices, there are some that are murky while others are clear with no pulp. Also, there are many different types of clear juices, such as those with darker tint and those that are completely transparent.

Translucent juices are used to clear-coat products, such as candies.

We had an opportunity to taste some of the juices.

It was hard to judge the slight differences in flavors. Also, for sour juices, its taste was too strong for me to judge flavors by a taste test.

Tasting their juice samples reminded me of flavors of all the different candies and snacks that I have had, and made me realize how widely their products are used.

QPlease tell us about the manufacturing process of your factory's juice products.

AThere are many steps to our manufacturing process, such as material receiving, defrosting, blending, sterilization, UF filtration, concentration, packaging; I will give you an overview of these processes.

First we must carry in the raw materials. We procure raw materials in its best condition; to maintain its quality, we manage the temperature conditions to be appropriate for each product. After preparation, products are boiled down or go through Ultrafiltration (UF).

During the heat concentration stage, we use the N-2E, N-3E Hand-held Refractometers to frequently check its Brix values. In order to preserve the natural taste of fruits, heating is performed swiftly.

Upon requests from customers, some of our products go through Ultrafiltration (UF). This process removes any insoluble solids that cause turbidity or sedimentation through membrane filtration. The size of the filter is a molecular weight cut-off (MWCO) of 6,000, which filters out most insoluble solids, producing high-quality clear juice concentrates.

Processed juices go in tanks, and every single tank is tested for quality. Only those that meet our QC standard can go on to the next stage, sterilization.

For sterilization, we use plate-type for juices and kneader-type and tubular-type for pulps.

Next is the packaging process. Here, the processed goods are filled into cans, sacks, or boxes to be shipped. Different types of packaging are used according to our customers' needs. We store products at the most appropriate temperature for each product, but most are stored frozen to preserve the flavor.

QDoing business with fruits must be hard since it's affected so much by weather.

AWhen we are obtaining raw materials, we always take into consideration the weather patterns and harvest seasons of the northern and southern hemispheres. We import from all over the world, and we perform inspections at production sites to maintain quality of all the ingredients.

QPlease tell us what makes your company special.

AOur company motto is "Everything Processed Fruits," and we pride ourselves in the wide variety fruits and processing methods we make available.

From small batches to unique orders, we can always tailor our products according to customers' needs.

We are working on perfecting our fit-to-need services from development to shipment to thoroughly support our customers.

Mr. Hosono, Mr. Haeno, and everyone in production control, thank you so much for kindly answering all of our questions.

We appreciate your continued support of ATAGO refractometers.

Refractometer RX-5000α

I am very pleased with the refractometer RX5000α. It is accurate unit, easy to use and clean. I like the fact it compensates for the temperature which is displayed on the read-out. Well designed and well made. Quality product!

Parle Agro Pvt. Ltd. is a beverage company who is known for, though not limited to, their mango juices. Popular juice brands Frooti and Appy are also a part of this company.

There are seven factory locations in India, and they are headquartered in Mumbai, Maharashtra. Parle Agro is a pioneer for commercial fruit beverages in India. They were the first to package juice in cartons and plastic bottles.

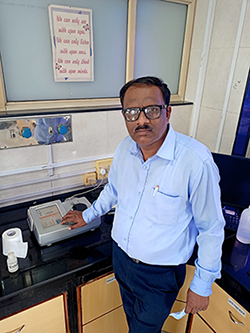

We visited their headquarter office and their quality control lab.

QWhat are your usages of the RX-5000α?

AWe take random samples from different branches and test them to see if they are within the Brix standard that our company has set.

QHow do you like the unit?

AIt is very user-friendly we are very satisfied with it. Readings are easy to take, and also it is easy to clean. We have nothing negative to say about the unit.

Parle Agro currently uses six ATAGO RX-5000α's.

Special thanks to Mr. Naik from the quality control department for his time and kindness to take us around the headquarter office and the lab. Thank you very much.

Parle Agro web site

http://www.parleagro.com/