Why an "Intrinsically Safe" Refractometer is Needed

In Plants Using Explosive Gases

Explosive gases are gases that have the property of exploding when mixed with air within a certain concentration range.

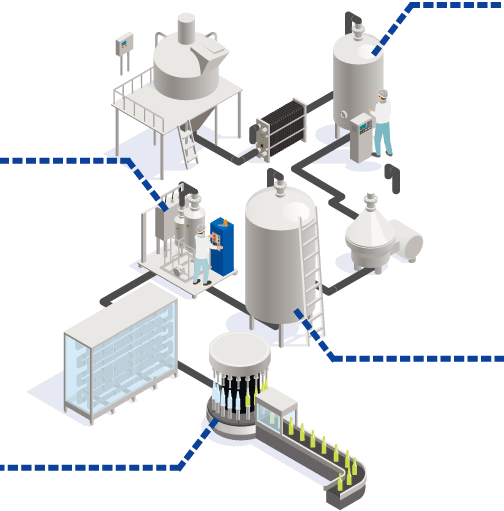

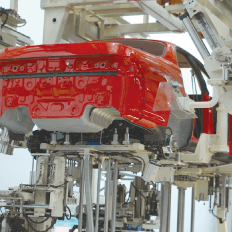

In environments such as chemical plants, refineries, and food factories, if gas leaks or is generated,it may ignite due to sparks or high temperatures, resulting in a greatly increased risk of explosion.

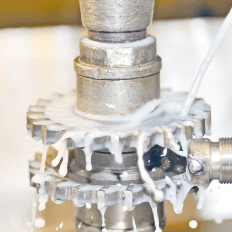

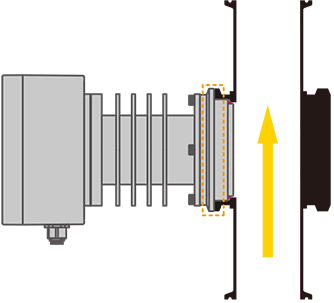

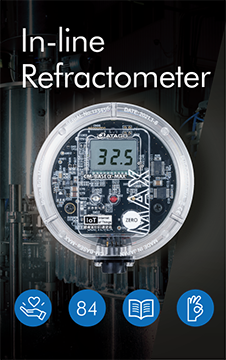

Refractometers for Use in Zone 0

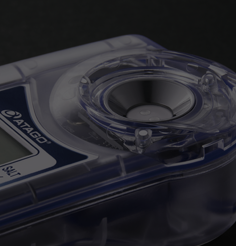

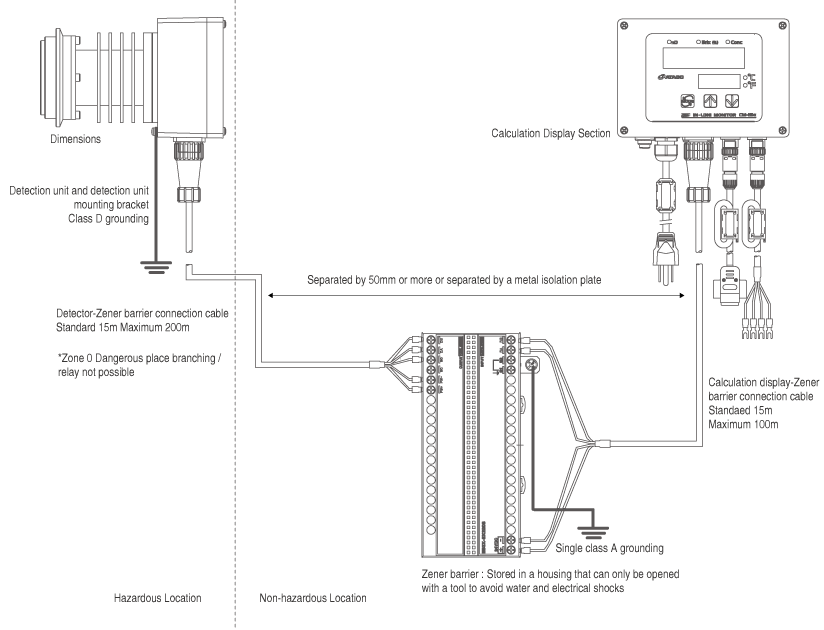

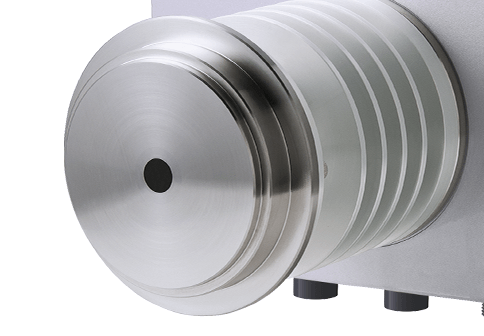

When using a refractometer in an environment where explosive gases are present,it must comply with Zone 0 (an environment where explosive gases are always present), and an intrinsically safe explosion-proof structure is the only design that can be used.

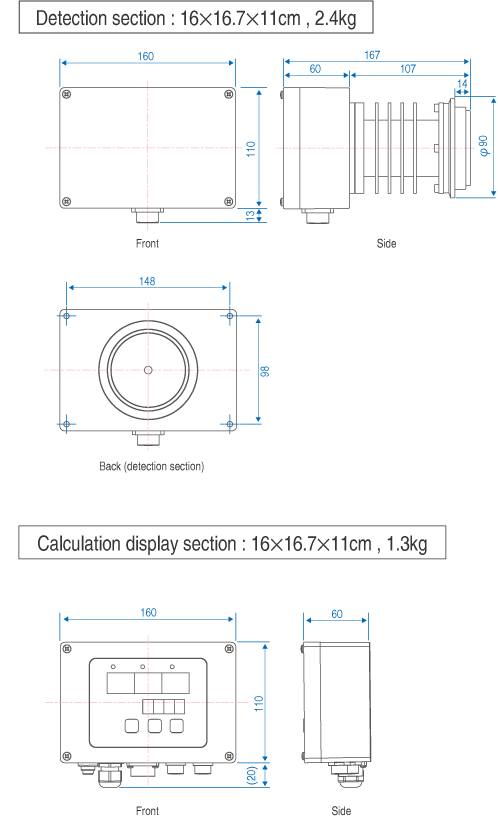

Therefore, the intrinsically safe CM-ISα is capable of performing accurate measurements while ensuring safety.

ys

ys