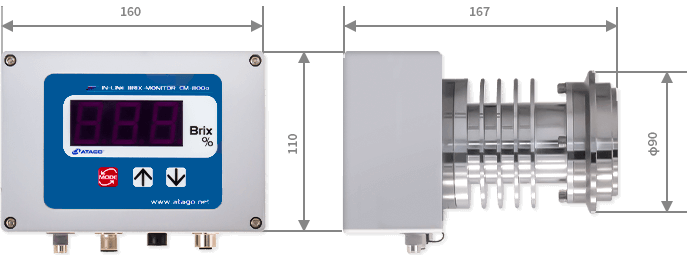

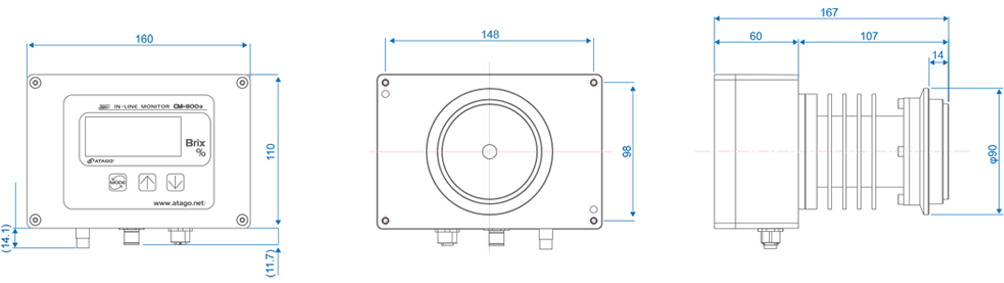

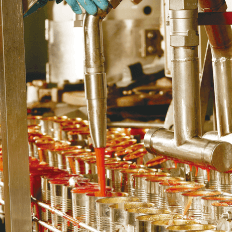

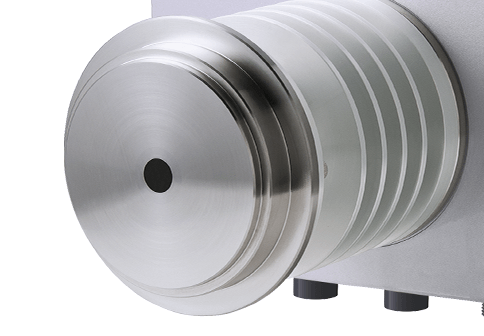

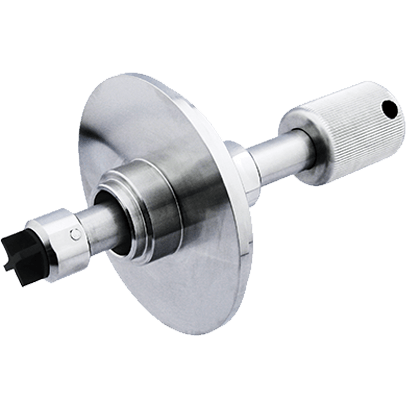

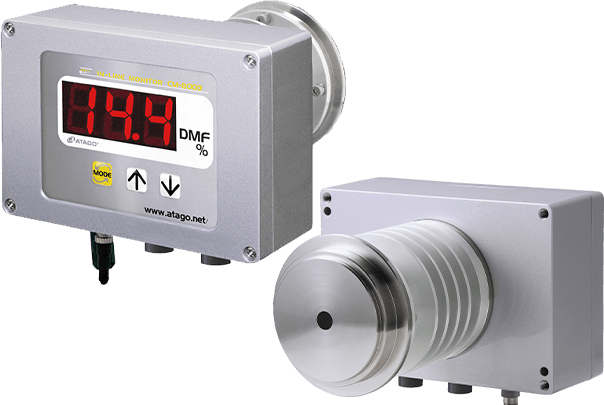

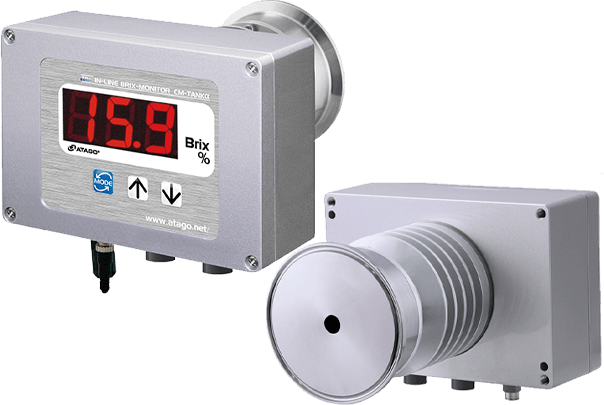

Wide range measurement and sufficient accuracy

Measures a wide range from 0.00 to 80.0% Brix with high accuracy of ±0.1%. A wide range of dedicated scales and an intrinsically safe explosion-proof model meet various needs.

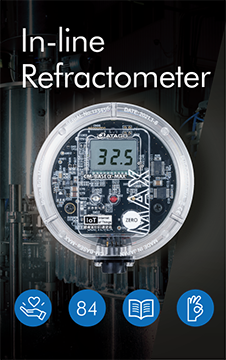

Seamless with two data outputs

Equipped with a DC 4mA to 20mA current output function for use with a recorder. Equipped with RS-232C data output for PC use.

Compatible with low and high temperatures

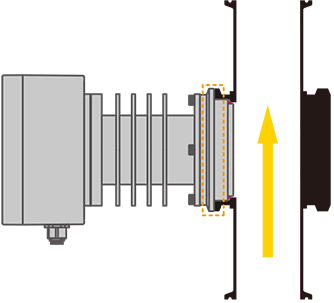

Equipped with an automatic temperature compensation function, it can handle a wide temperature range from 5°C to 100°C. The wetted surface can withstand temperatures up to 160°C, allowing for safe CIP and SIP cleaning.

Compatible with strong acids and strong alkalis

We offer customized wetted surfaces for measuring chemical samples. The standard stainless steel specification can be upgraded to Hastelloy or titanium. Because all metals are machined and polished in-house, we are flexible in accommodating material changes.

ys

ys