DMF is used as a solvent for polyurethane in the production of artificial leather. First, a non-woven fabric is impregnated with a water-based aqueous solution containing a surfactant.Then, it is dipped in a DMF solution in a coagulation bath to undergo urethane formation reaction.

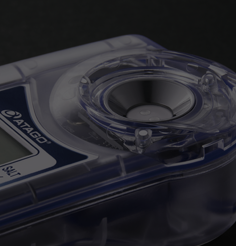

Since the DMF solution in the coagulation bath is gradually diluted with water from the previous step, the concentration control of the DMF aqueous solution is important because its quality affects the concentration. The DMF solution in the coagulation process is recycled through the recovery system, and in some cases, a refractometer is built into the recovery system.

The method of producing artificial leather varies depending on the application, and a DMF solution may be used in the impregnation process.

ys

ys

DMF : Dimethylformamide

DMAC:Dimethylacetamide

DMSO: Dimethylsulfoxide

These are widely used as solvents.

Dimethylformamide (DMF) may be unfamiliar name but it is very much used in the acrylic fiber forming and as a solvent for wet spinning. It is also used as a solvent for artificial leather and urethane-based synthetic leather.